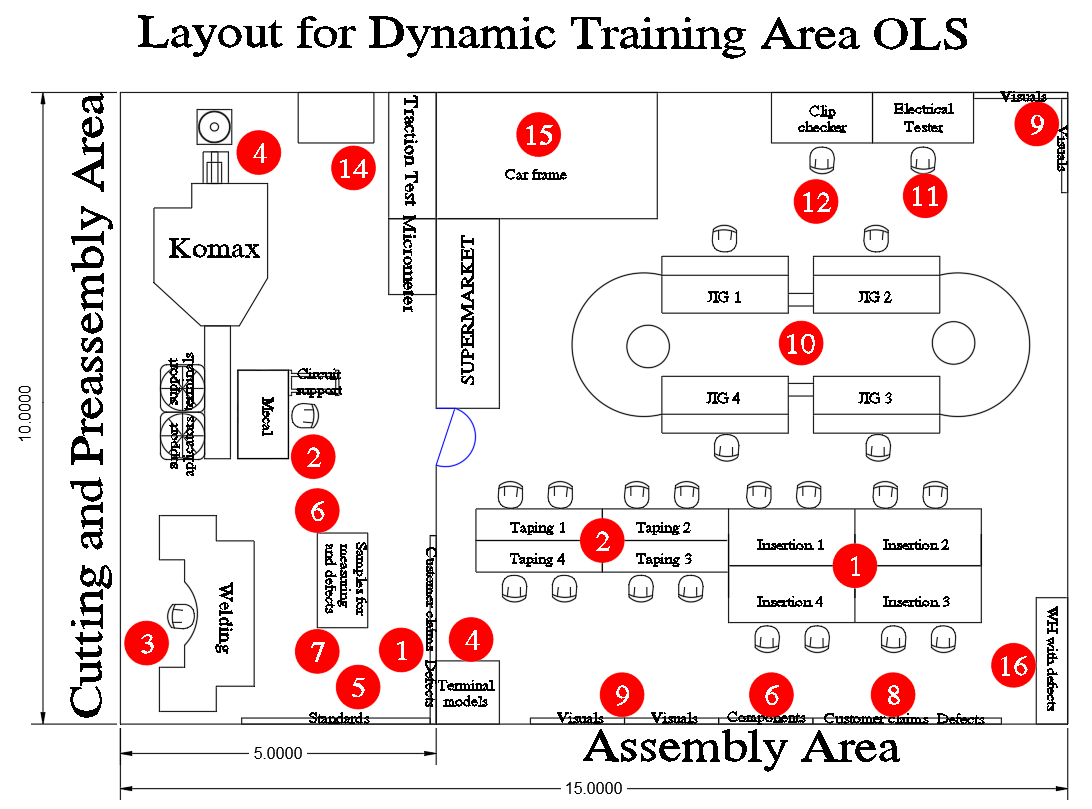

OLS Training Area CAD Layout with Cutting and Assembly Zones

Description

This detailed OLS Dynamic Training Area layout presents a complete industrial learning environment designed to support operator skill development and structured manufacturing training. The drawing is divided into two major functional zones, which are the Cutting and Preassembly Area and the Assembly Area. The left section includes Komax machines, winding stations, circuit support points, micrometers, traction test locations, terminal model tables, standards benches, and workstation setups used for teaching cable preparation and component handling. All activity points are numbered for easy identification and reflect the actual workflow found in production units. The use of clear labels, dimension references, and functional grouping helps trainers organize step-by-step learning tasks for new operators.

The right section displays the Assembly Area where trainees practice taping processes, insertion activities, electrical verification, clip checking, JIG operations, and quality inspection routines. Seating arrangements and workstation positions are carefully placed to support team-based learning. The layout also includes supermarket storage, component tables, final defect inspection areas, and visual boards that reinforce training discipline. This drawing provides a comprehensive view of a fully operational OLS learning environment, allowing users to study workflow sequence, optimize workstation placement, and simulate real production activities with accuracy and clarity.

Uploaded by:

Eiz

Luna