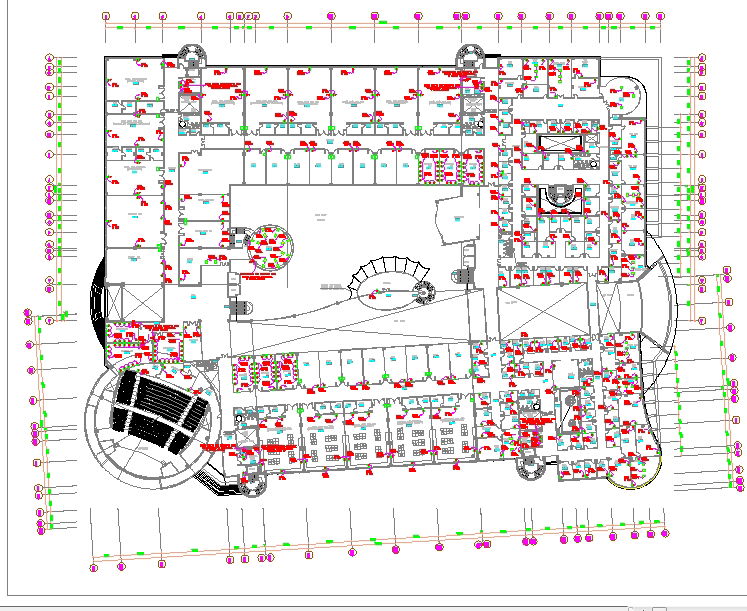

Electrical Layout Floor Plan with Complete Wiring and Lighting

Description

This AutoCAD DWG file presents a detailed electrical layout floor plan designed for a multi-purpose commercial or institutional building. The plan includes complete lighting, power distribution, and wiring routes across all rooms, corridors, and exterior zones. It highlights socket placements, electrical symbols, panel boards, and switch controls, ensuring full coverage for interior and exterior circuits.

Each room’s electrical components are carefully mapped, showing connections for lighting fixtures, ceiling fans, and emergency power systems. The plan also provides conduit pathways, switchboards, and floor-level cabling routes with clear labeling for easy identification and installation accuracy. Additionally, the central courtyard and circular auditorium area include distinct lighting arrangements optimized for energy efficiency.

This drawing is an ideal resource for architects, electrical engineers, and builders involved in design implementation and safety planning. By subscribing to Cadbull, users can access and download thousands of similar AutoCAD electrical layout DWG files, ensuring professional-grade precision in every project.

File Type:

DWG

File Size:

1.5 MB

Category::

Electrical

Sub Category::

Architecture Electrical Plans

type:

Free

Uploaded by:

muhammad

yousaf