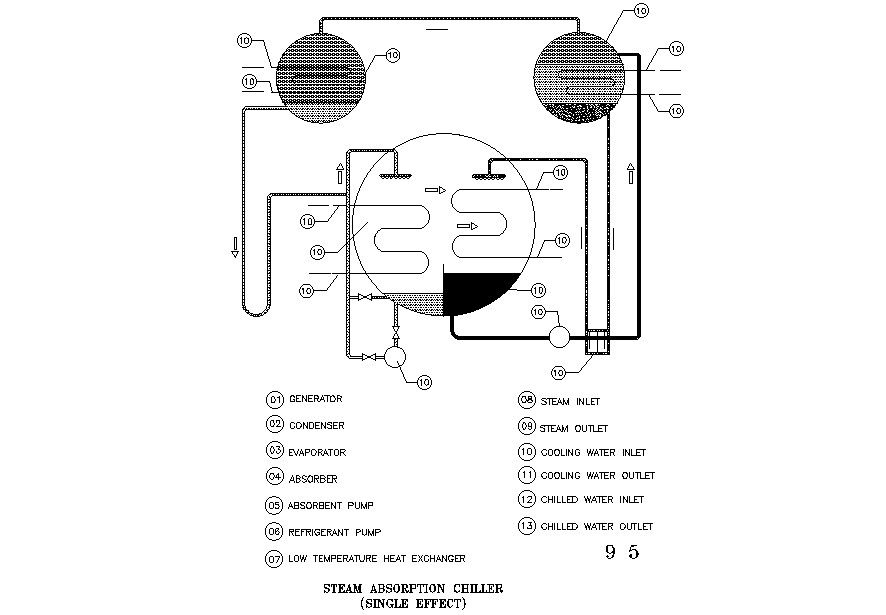

Steam absorption chiller

Description

Here absorption chiller diagram his absorption cooling cycle relies on three basic principles: When a liquid is heated it boils (vaporizes) and when a gas is cooled it condenses. Lowering the pressure above a liquid reduces its boiling point. Heat flows from warmer to cooler surfaces. An absorption chiller is consisted of four main parts: generators, condensers, evaporators, and absorbs. We can model the absorption chiller by considering the energy balance in the four parts. Absorption chillers collect waste heat from other processes and equipment to drive thermodynamic processes that allows water to be chilled and distributed for HVAC needs. Absorption chillers do not use mechanical compressors, instead making use of the absorption refrigeration cycle. Accepted refrigerants for this application are: R-410A, R-404A, R-407C and R-134a are accepted on all chillers, except for those with scroll compressors. However the GWP of these refrigerants is high, thus their prices are increasing and availability is decreasing

Uploaded by:

zalak

prajapati